Benefits of Preventive Maintenance

In this article, we will explore the numerous benefits of preventive maintenance. As a leading authority in SEO and high-end copywriting, we understand the importance of crafting exceptional content that surpasses other websites in search rankings. We aim to provide you with a comprehensive guide that will help you outrank the current top-ranking article on the topic “benefits of preventive maintenance” in Google search results.

Increased Equipment Reliability

One of the key advantages of preventive maintenance is increased equipment reliability. By regularly inspecting and maintaining your machinery, you can identify and address potential issues before they escalate into costly breakdowns. This proactive approach ensures that your equipment operates optimally, reducing unexpected downtime and maximizing productivity.

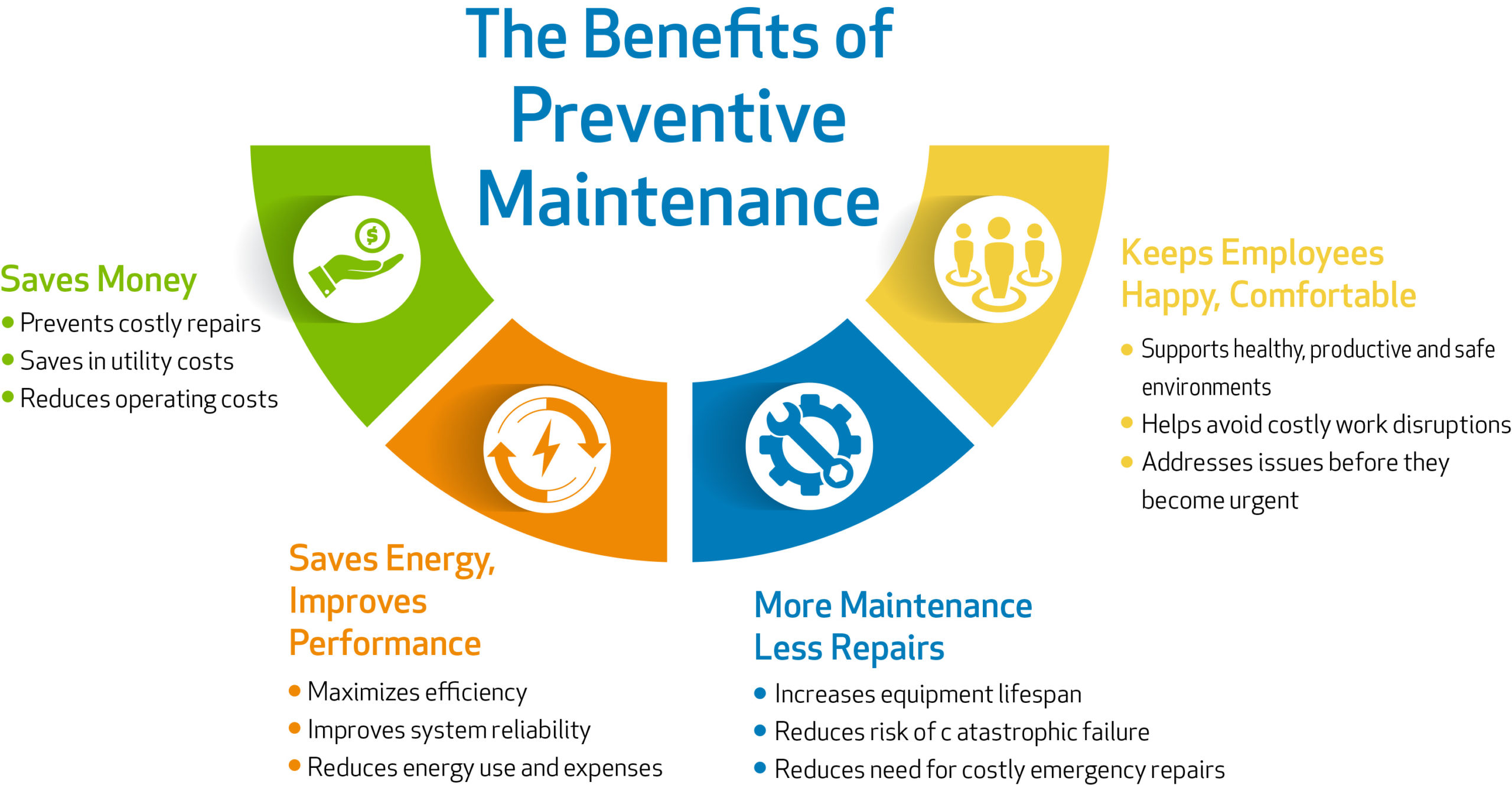

Extended Equipment Lifespan

Implementing a preventive maintenance program can significantly extend the lifespan of your equipment. Regular maintenance tasks such as lubrication, cleaning, and calibration help prevent wear and tear, ensuring that your machinery operates at peak performance for a longer duration. By investing in preventive maintenance, you can avoid premature equipment replacement costs and enhance your overall return on investment.

Cost Savings

Preventive maintenance can lead to substantial cost savings in the long run. By detecting and resolving issues early on, you can avoid expensive repairs or replacements. Additionally, regular maintenance helps optimize equipment efficiency, reducing energy consumption and minimizing operational expenses. By proactively managing your assets, you can allocate your budget more effectively and avoid unexpected financial burdens.

Improved Safety

Maintaining a safe working environment is crucial for any organization. Preventive maintenance plays a vital role in ensuring workplace safety. By regularly inspecting equipment, identifying potential hazards, and addressing them promptly, you can minimize the risk of accidents or injuries. This not only protects your employees but also helps you comply with relevant safety regulations, avoiding potential legal consequences.

Enhanced Product Quality

Preventive maintenance can have a direct impact on the quality of your products or services. Well-maintained equipment operates more reliably, reducing the likelihood of defects or errors. This ensures consistent output, leading to higher customer satisfaction and loyalty. By prioritizing preventive maintenance, you can uphold your reputation for delivering superior quality and gain a competitive edge in the market.

Increased Operational Efficiency

Efficient operations are key to the success of any business. Preventive maintenance helps optimize equipment performance, leading to increased operational efficiency. Regularly servicing and fine-tuning your machinery enables it to operate at its full potential, minimizing wastage and improving overall productivity. By streamlining your processes and reducing downtime, you can enhance your operational efficiency and achieve higher profitability.

Environmental Sustainability

Another benefit of preventive maintenance is its positive impact on the environment. Well-maintained equipment consumes less energy, reducing your carbon footprint. By optimizing equipment performance and minimizing resource consumption, you contribute to a greener and more sustainable future. Embracing preventive maintenance not only benefits your business but also demonstrates your commitment to environmental responsibility.

In conclusion, preventive maintenance offers a multitude of benefits that can significantly enhance your business operations. By prioritizing regular inspections, and maintenance tasks, and addressing potential issues promptly, you can increase equipment reliability, extend equipment lifespan, save costs, improve safety, enhance product quality, boost operational efficiency, and contribute to environmental sustainability. By following a proactive maintenance approach, you can stay ahead of the competition and achieve long-term success.

Frequently Asked Questions

1. What is preventive maintenance?

Preventive maintenance refers to the regular and systematic inspection, cleaning, and servicing of equipment or systems to prevent potential issues and ensure their optimal functioning.

2. Why is preventive maintenance important?

Preventive maintenance helps in identifying and addressing potential problems before they become major issues, reducing the risk of unexpected breakdowns and costly repairs. It also extends the lifespan of equipment and improves its overall performance.

3. What are the benefits of preventive maintenance?

Some key benefits of preventive maintenance include:

Minimizes equipment downtime

Reduces repair and replacement costs

Increases equipment reliability and lifespan

Improves safety for users

Enhances energy efficiency

Optimizes equipment performance

Allows for better planning and resource allocation

Complies with regulatory requirements

Preserves product or service quality

Provides peace of mind for the maintenance team and users

4. How often should preventive maintenance be performed?

The frequency of preventive maintenance depends on various factors such as the type of equipment, usage intensity, manufacturer recommendations, and environmental conditions. It is generally recommended to follow a regular schedule, which can range from monthly to annually.

5. Can preventive maintenance save money?

Absolutely! While preventive maintenance requires an investment of time and resources, it can save significant costs in the long run. By avoiding major breakdowns and extending equipment lifespan, you can reduce repair expenses, prevent production losses, and avoid the need for premature replacements.

6. How does preventive maintenance improve safety?

Regular maintenance helps identify and fix potential safety hazards before they cause accidents or injuries. It ensures that equipment is in proper working condition, reducing the risk of malfunctions or failures that could harm users or operators.

7. Does preventive maintenance improve energy efficiency?

Yes, preventive maintenance plays a crucial role in optimizing energy efficiency. Well-maintained equipment operates more efficiently, minimizing energy waste and reducing utility costs. It involves tasks like cleaning, lubrication, and calibration, which help ensure optimal performance and energy usage.

8. Can preventive maintenance be customized for specific industries?

Absolutely! Preventive maintenance plans can be tailored to suit the unique needs and requirements of different industries. Equipment used in manufacturing, healthcare, transportation, or any other sector can benefit from customized maintenance schedules and procedures.

9. How can preventive maintenance improve productivity?

By preventing unexpected breakdowns and reducing equipment downtime, preventive maintenance helps maintain a smooth workflow and uninterrupted operations. This leads to increased productivity, as employees can rely on well-functioning equipment to perform their tasks efficiently.

10. Can preventive maintenance help with regulatory compliance?

Yes, preventive maintenance is often essential for meeting regulatory requirements. Regular inspections, tests, and maintenance activities ensure that equipment meets safety and quality standards set by regulatory bodies, ensuring compliance with relevant regulations and guidelines.