The Benefits of 5S: Achieve Efficiency and Organization

Welcome to our comprehensive guide on the benefits of 5S. In this article, we will explore how implementing the 5S methodology can help businesses achieve efficiency and organization. Whether you are a small startup or a large corporation, 5S can revolutionize your workplace and improve overall productivity. Let’s dive in!

What is 5S?

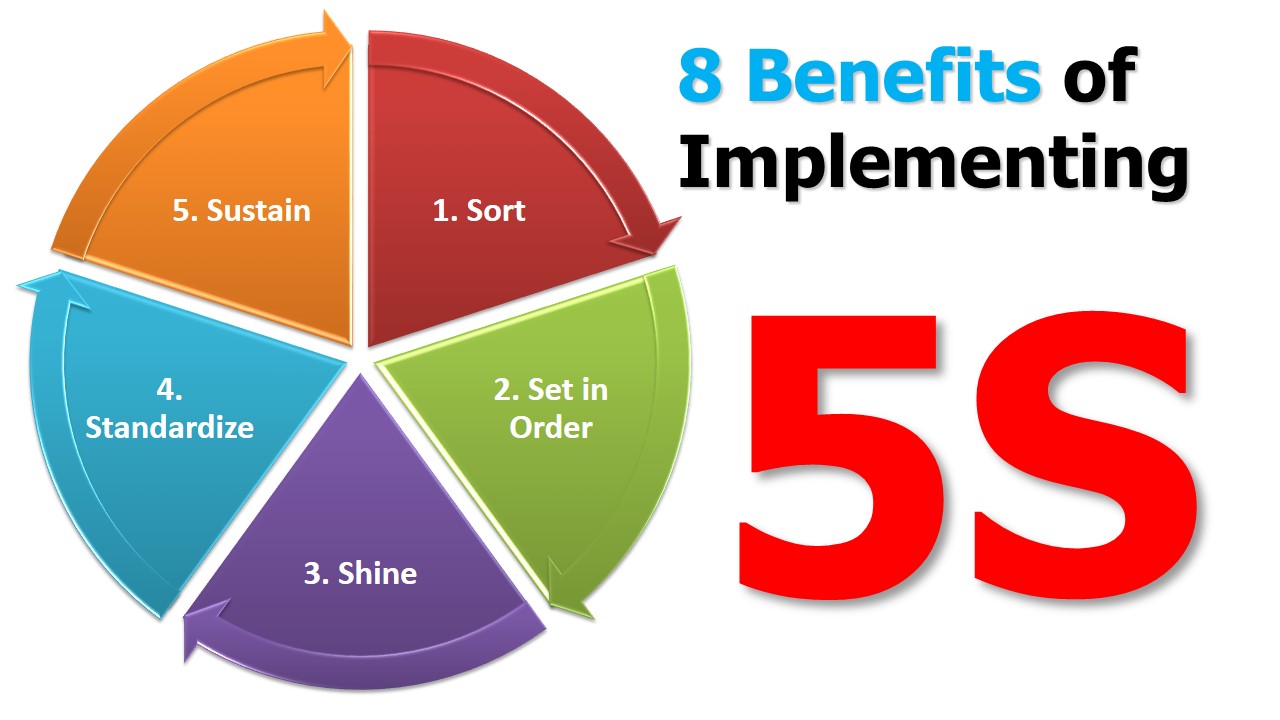

5S is a systematic approach to workplace organization and standardization. It originated in Japan and is derived from five Japanese words: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). Each of these steps plays a crucial role in creating a clean, organized, and efficient work environment.

The Benefits of 5S

Increased Efficiency

Implementing 5S practices in your workplace leads to increased efficiency. By eliminating clutter and unnecessary items, employees can easily locate tools, equipment, and materials. This reduces time wasted searching for items and allows for a smoother workflow. With everything in its designated place, tasks can be completed more quickly and efficiently.

Improved Productivity

When employees have a clean and organized workspace, it positively impacts their productivity. A clutter-free environment promotes focus and reduces distractions. By implementing 5S, you create an environment that enables employees to work more efficiently, leading to increased productivity and output.

Enhanced Safety

Workplace safety is a top priority for any organization. 5S helps create a safer work environment by eliminating hazards and reducing the risk of accidents. With tools and equipment properly stored and labeled, employees can easily identify potential dangers. Additionally, regular cleaning and maintenance under the Seiso step ensure a safe and healthy workplace.

Streamlined Processes

5S promotes the streamlining of processes within an organization. By analyzing workflows during the Seiri and Seiton steps, inefficiencies and bottlenecks can be identified and eliminated. This leads to smoother and more streamlined processes, reducing waste and improving overall productivity.

Employee Morale and Engagement

A clean and organized workspace has a positive impact on employee morale and engagement. When employees feel comfortable and proud of their work environment, it boosts their motivation and satisfaction. 5S fosters a sense of ownership and responsibility among employees, as they actively participate in maintaining the organized workplace.

Cost Savings

Implementing 5S practices can result in significant cost savings for businesses. By eliminating waste, reducing the need for excess inventory, and optimizing processes, organizations can save both time and money. Additionally, a clean and organized workplace reduces the risk of equipment damage or loss, further contributing to cost savings.

Implementing 5S in Your Workplace

Now that we have explored the benefits of 5S, let’s discuss how you can implement this methodology in your workplace. It is important to involve all employees in the process and provide adequate training and resources. Here are the steps to get started:

Sort (Seiri)

Start by sorting through all items in the workplace. Identify what is necessary and what is not. Remove any unnecessary items that are taking up space and cluttering the workspace.

Set in Order (Seiton)

Designate a specific place for each item and clearly label storage areas. Ensure that frequently used items are easily accessible and that there is a logical flow to the workspace layout.

Shine (Seiso)

Regularly clean and maintain the workplace. Encourage employees to take responsibility for their work areas and keep them clean and organized. This step helps identify and address any potential safety hazards.

Standardize (Seiketsu)

Establish standard procedures and guidelines for maintaining an organized workplace. Document these procedures and ensure that all employees are trained and aware of them. Regularly review and update the standards as needed.

Sustain (Shitsuke)

Maintaining the 5S practices is crucial for long-term success. Encourage employee participation and engagement in sustaining the organized workplace. Regularly evaluate and monitor the adherence to 5S principles.

In conclusion, implementing the 5S methodology in your workplace brings numerous benefits, including increased efficiency, improved productivity, enhanced safety, streamlined processes, higher employee morale, and cost savings. By following the five steps of 5S, you can transform your work environment into a well-organized and highly productive space. Start your 5S journey today and experience the positive impact it can have on your business!

Frequently Asked Questions about the Benefits of 5S

1. What is 5S?

5S is a methodology used to organize and improve the workplace. It consists of five steps: Sort, Set in Order, Shine, Standardize, and Sustain.

2. How does 5S benefit a company?

Implementing 5S can lead to improved efficiency, productivity, and safety in the workplace. It also helps reduce waste, increase employee morale, and create a visually organized work environment.

3. Can 5S improve workplace safety?

Yes, 5S can greatly improve workplace safety. By organizing and removing unnecessary items, it reduces the risk of accidents and injuries. Clear pathways and labeled storage also contribute to a safer work environment.

4. Does 5S help with inventory management?

Absolutely! 5S helps companies better manage their inventory by creating a visual system for storage and ensuring items are easily accessible. This reduces stockouts, improves inventory turnover, and minimizes excess inventory.

5. How does 5S impact employee morale?

Implementing 5S shows employees that their work environment is valued and cared for. This can boost morale and engagement, as employees feel more organized, productive, and proud of their workplace.

6. Can 5S benefit customer satisfaction?

Yes, it can. By implementing 5S, companies can improve their processes, reduce errors, and deliver products or services more efficiently. This leads to increased customer satisfaction and loyalty.

7. Is 5S only applicable to manufacturing industries?

No, 5S principles can be applied to any industry or workplace, including offices, healthcare facilities, retail stores, and more. It is a versatile methodology that can benefit any organization.

8. How long does it take to implement 5S?

The time required to implement 5S varies depending on the size and complexity of the workplace. It can range from a few weeks to several months. However, it is an ongoing process that requires continuous improvement and maintenance.

9. Are there any cost savings associated with 5S?

Yes, 5S can result in cost savings for companies. By eliminating waste, improving efficiency, and reducing errors, organizations can save money on materials, labor, and rework.

10. Can 5S help with employee productivity?

Definitely! 5S creates an organized and clutter-free workspace, making it easier for employees to find tools, equipment, and information. This saves time, reduces frustration, and increases overall productivity.