Demo published

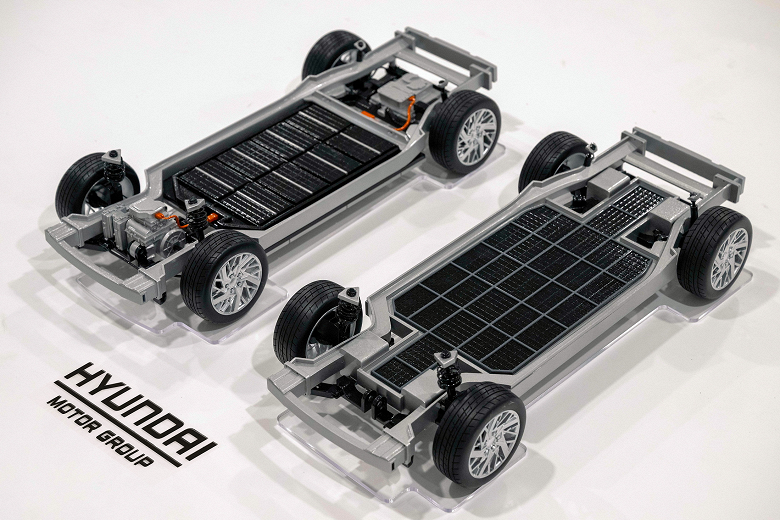

Hyundai says it has developed new technology that will allow it to significantly reduce the size of electric motors, creating more space for people and their belongings.

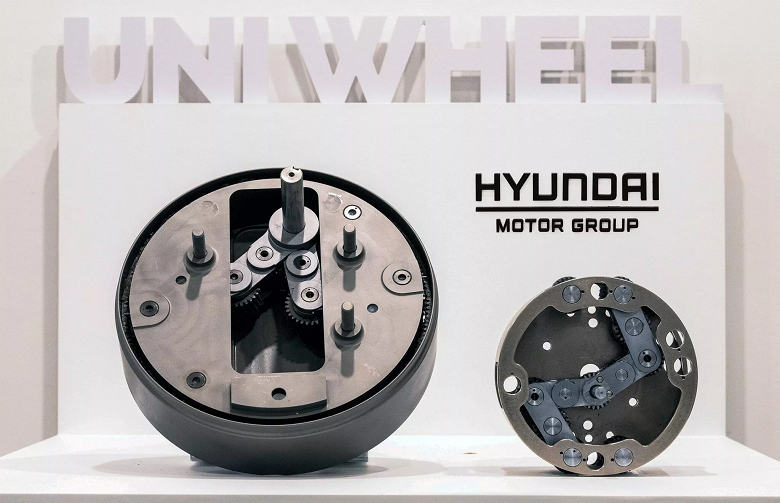

The innovation was called Uni Wheel . This design moves the gearbox into the wheel hub, effectively reducing the size of the motor. This innovation allows Hyundai to use one small motor per wheel instead of relying on a large drive for the entire axle.

Hyundai Uni Wheel system introduced.

By using a series of gears located inside the wheel, the power of even a small engine is transferred to the wheel with enough torque to move the vehicle. Individual activation of each wheel has benefits in terms of driving performance and safety.

Thanks to the design of the gears, they can move inside the hub while transmitting power. As a result, the connection between the wheel and the engine can slide up and down freely, so the wheel does not require a CV joint. This means that the efficiency losses associated with operating such a connection at an angle are eliminated, improving power delivery.

The freedom provided by this technology allows engineers greater control over the vehicle’s ride height. Cars equipped with the Uni Wheel can be pressed down for an aerodynamic highway ride or increased ground clearance without sacrificing power.

Hyundai says the Uni Wheel can be squeezed into wheels as small as four inches in diameter. It can also be scaled to handle wheels up to 25 inches for larger vehicles such as cars and SUVs.

The company says it tested the system for durability and the Uni Wheel performed well. Unfortunately, The Korea Times reports that Hyundai is not yet ready to say when the Uni Wheel will be ready to go into production, but the company has filed patents in key markets: Korea, Europe and the United States.