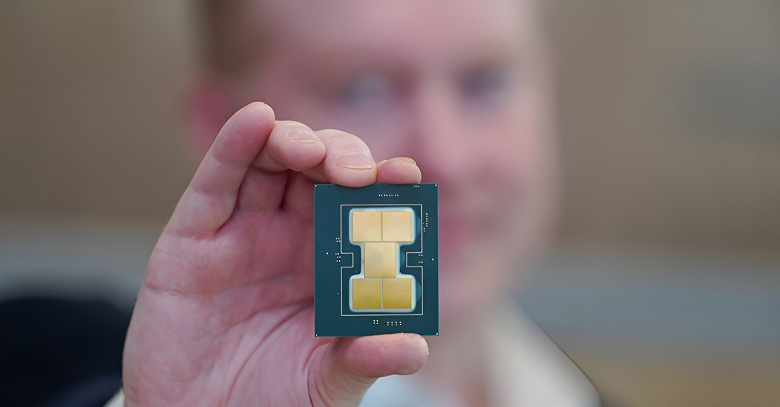

Intel admitted that the rejection of monolithic crystals will reduce the cost of production

Intel CEO Robert Swan represented the company at Credit Suisse’s virtual conference this week, and his talk could be given a little more attention. Speaking about layout solutions, the head of Intel admits that the use of chiplets can reduce the cost of production.