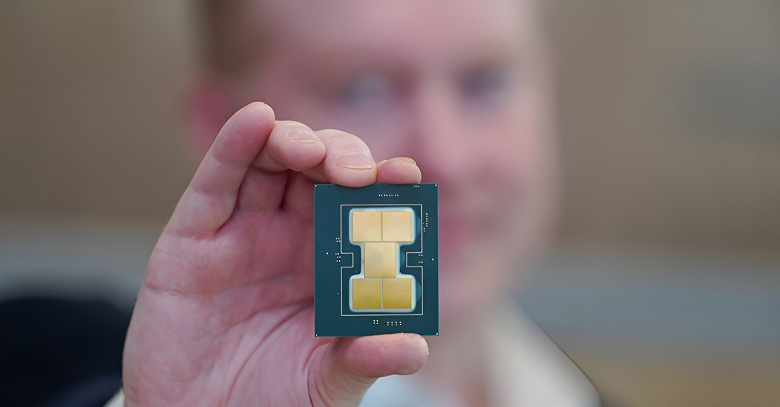

Intel explains why its multi-die arrangement on a single substrate is better than AMD chiplets

Intel’s event yesterday made it possible to make sure that the company’s specialists could create the Ponte Vecchio computing accelerator from 47 silicon cells, which contain a total of 100 billion transistors. Intel’s head urges not to confuse proprietary layout solutions with AMD chipsets, at the same time explaining why his company’s approach is better.

As noted, new Intel CEO Pat Gelsinger has urged not to use the term “chipset” to refer to individual elements of the Ponte Vecchio. According to him, it is more correct to call each crystal a “tile,” and PC Gamer saw it necessary to explain the fundamental difference in Intel and AMD’s layout approaches.

According to the source, the latter requires a rather wide bus to coordinate the operation of individual chiplets and implement data exchange between them, which hides the “transistor budget” and complicates the product layout. Intel, in its layout techniques Foveros and EMIB, uses rather short conductors that run perpendicular to the plane of the crystal in the first case and parallel in the second. Neighboring dies on such a substrate do not require any buffers or buses for matching. This makes it possible to increase the density of the placement of elements on the same area and facilitates the integration of dissimilar crystals made by different lithographic technologies and even by different companies.

As you know, monolithic crystals are quite expensive to manufacture. In the case of 14nm technology, this has played a cruel joke on Intel more than once. Having delayed the 10nm technical process development, it was forced to produce more and more large enough 14nm crystals. As a result, the available production capacity ceased to suffice. Even with Rocket Lake processors’ creation, the need to limit the die area forced engineers to limit the number of computing cores to eight pieces. However, the Comet Lake family’s flagship models previously offered ten cores on one die. Moving to new packaging methods will allow Intel to avoid such restrictions in the future. However, it is understandable that it will require additional costs and will not reach the brand’s mainstream products so soon.