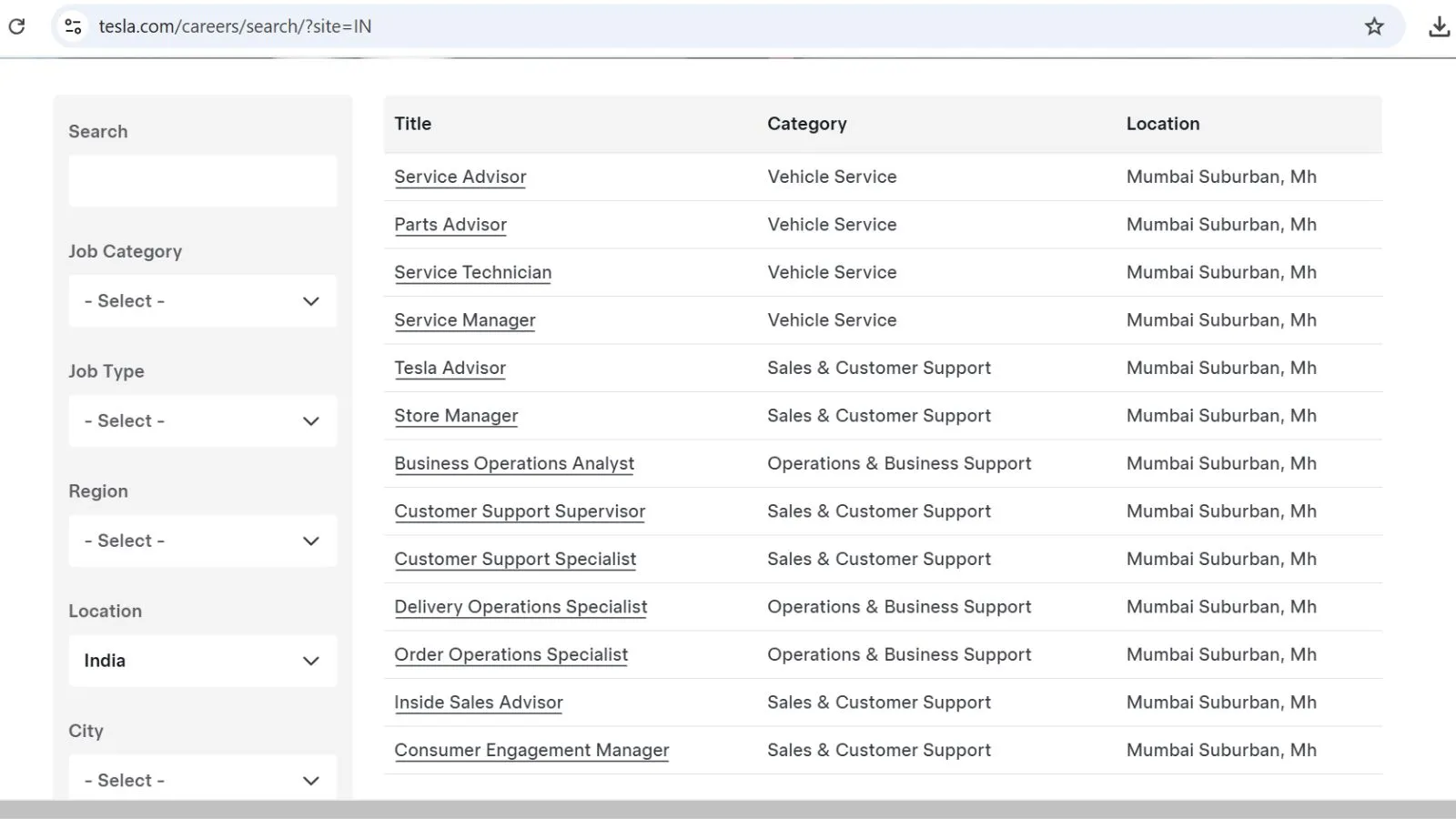

These battery cells are from the Roadrunner project

Elon Musk promised a lot of interesting things on September 22 at the Tesla Battery Day event. The most important event will be the announcement of a new traction battery at a price of $ 100 per 1 kWh – it will significantly reduce the cost of production of electric vehicles, which in some way will become a small revolution in the automotive industry. And it is already known what such a traction battery will consist of.

Tesla’s Revolutionary Biscuit Battery Technology

Images of new battery cells created by Tesla itself as part of the Roadrunner project have appeared on the web. They will also be produced by Tesla. For their characteristic shape, these batteries have been dubbed Biscuit Tin – “a tin for biscuit cookies.” In shape, the novelty resembles an element of the 2170 format (21 mm – diameter, 70 mm – height), used in electric vehicles now, but its diameter is noticeably large at about the same or slightly higher height. It is believed that the new format will increase the specific gravity of the traction battery: doubling the diameter translates into a fourfold increase in cell capacity. At the same time, costs are reduced – due to the use of fewer elements in the traction battery and a smaller volume of shell materials.

The 2170 cells are manufactured by Panasonic at the Gigafactory Nevada and are installed in Model 3 and Model Y. Biscuit battery cells will be produced by Tesla in a separate factory near the Fremont headquarters. They are likely to be used in all of the company’s new cars: the second-generation Tesla Model S and Model X, as well as the Cybertruck armored truck.