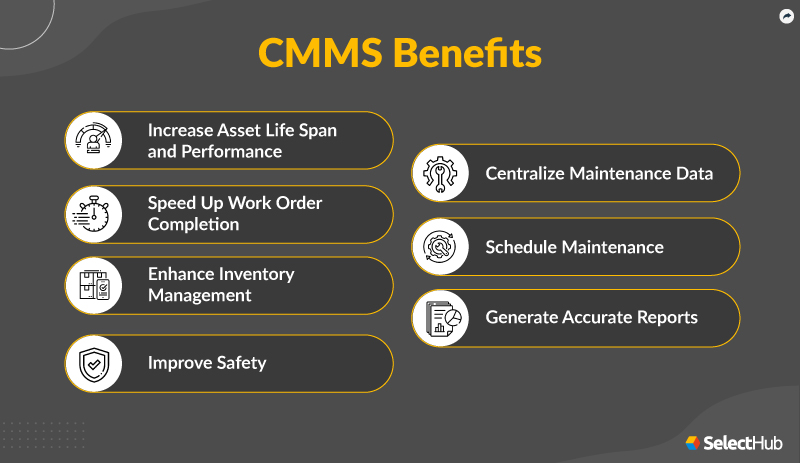

Benefits of CMMS

CMMS, which stands for Computerized Maintenance Management System, is a powerful tool that can revolutionize the way businesses manage their maintenance operations. In this article, we will explore the various benefits of implementing a CMMS and how it can help you streamline your maintenance processes and improve overall efficiency.

Increased Equipment Reliability

One of the key benefits of using a CMMS is the ability to enhance equipment reliability. By implementing a preventive maintenance program through the CMMS, you can schedule regular inspections, lubrications, and other maintenance tasks to ensure that equipment is in optimal condition. This proactive approach helps identify potential issues before they turn into major problems, reducing unplanned downtime and costly repairs.

Improved Maintenance Planning

A CMMS provides a centralized platform to manage all maintenance activities, allowing you to efficiently plan and schedule tasks. With a CMMS, you can easily assign work orders to technicians, track their progress, and ensure that maintenance tasks are completed on time. This improves resource allocation, reduces downtime, and increases the overall productivity of your maintenance team.

Enhanced Inventory Management

Effective inventory management is crucial for any maintenance operation. A CMMS helps you keep track of spare parts, tools, and other inventory items. By maintaining an accurate inventory record, you can avoid stockouts and ensure that you have the necessary parts available when needed. This minimizes equipment downtime and reduces the need for emergency purchases, ultimately saving costs.

Streamlined Communication

Communication is key in any organization, and a CMMS facilitates seamless communication between maintenance technicians, managers, and other stakeholders. Through the CMMS, technicians can easily report issues, update work order statuses, and request assistance. Managers can track progress, assign priorities, and provide necessary instructions. This streamlined communication ensures that everyone is on the same page, leading to faster response times and improved efficiency.

Accurate Data and Reporting

A CMMS provides real-time data on maintenance activities, allowing you to make data-driven decisions. You can generate reports on equipment performance, maintenance costs, work order history, and more. These insights help identify trends, analyze the effectiveness of maintenance strategies, and make informed decisions to optimize your maintenance processes.

Increased Regulatory Compliance

For businesses operating in industries with strict regulatory requirements, maintaining compliance is crucial. A CMMS helps you stay on top of compliance by tracking maintenance activities, ensuring that inspections and audits are conducted as per regulations, and maintaining accurate records. This reduces the risk of penalties, legal issues, and reputational damage.

In conclusion, implementing a CMMS offers numerous benefits for businesses. From increased equipment reliability and improved maintenance planning to enhanced inventory management and streamlined communication, a CMMS can transform your maintenance operations and drive overall efficiency. By leveraging the power of technology and data, you can stay ahead of the competition and achieve long-term success in your industry.

Frequently Asked Questions – Benefits of CMMS

1. What is CMMS and why is it beneficial?

CMMS stands for Computerized Maintenance Management System. It is beneficial because it helps organizations streamline their maintenance operations, improve asset reliability, reduce downtime, and increase overall productivity.

2. How can CMMS help in reducing maintenance costs?

CMMS enables proactive maintenance planning, scheduling, and asset tracking, which helps prevent costly breakdowns and extends equipment lifespan. It also optimizes inventory management, reducing unnecessary purchases and minimizing downtime due to parts unavailability.

3. What are the advantages of using CMMS for work order management?

CMMS simplifies work order creation, assignment, and tracking. It ensures that maintenance tasks are completed on time, improves communication between team members, and provides a centralized platform for documentation and reporting.

4. Can CMMS improve equipment reliability?

Yes, CMMS can improve equipment reliability by implementing preventive maintenance programs. It enables regular inspections, lubrication, and calibration, reducing the chances of unexpected breakdowns and extending the life of assets.

5. How does CMMS enhance inventory management?

CMMS provides real-time visibility into inventory levels, automates reordering processes, and tracks usage patterns. It helps organizations maintain optimal stock levels, avoid stockouts, and reduce excess inventory, leading to cost savings.

6. Can CMMS help in regulatory compliance?

Yes, CMMS helps organizations comply with regulatory standards by ensuring proper maintenance of equipment, generating audit trails, and facilitating documentation for inspections. It helps avoid penalties and maintain a safe working environment.

7. What are the benefits of CMMS for asset lifecycle management?

CMMS enables organizations to track and manage assets throughout their lifecycle. It helps in planning asset replacements, optimizing maintenance schedules, and making informed decisions regarding repairs, upgrades, or retirements.

8. How can CMMS improve communication within maintenance teams?

CMMS provides a centralized platform for communication, allowing team members to collaborate, share information, and receive real-time updates on work orders, tasks, and equipment status. It eliminates manual communication gaps and improves overall efficiency.

9. Does CMMS help in data-driven decision-making?

Yes, CMMS collects and analyzes maintenance data, generating insightful reports and performance metrics. These data-driven insights enable organizations to identify trends, optimize maintenance strategies, allocate resources effectively, and make informed decisions.

10. What are the productivity benefits of implementing CMMS?

CMMS improves productivity by reducing equipment downtime, minimizing manual paperwork, automating routine tasks, and enabling efficient resource allocation. It empowers maintenance teams to focus on critical tasks and enhances overall operational efficiency.